Ever had a 3D print fail and leave behind a messy blob of plastic? That’s often called “spaghetti,” and AI can now detect it before things get worse. This blog explains how do 3D printers pause when AI spaghetti detection triggers, saving time and materials.

Stick around to learn how this smart tech works!

Key Takeaways

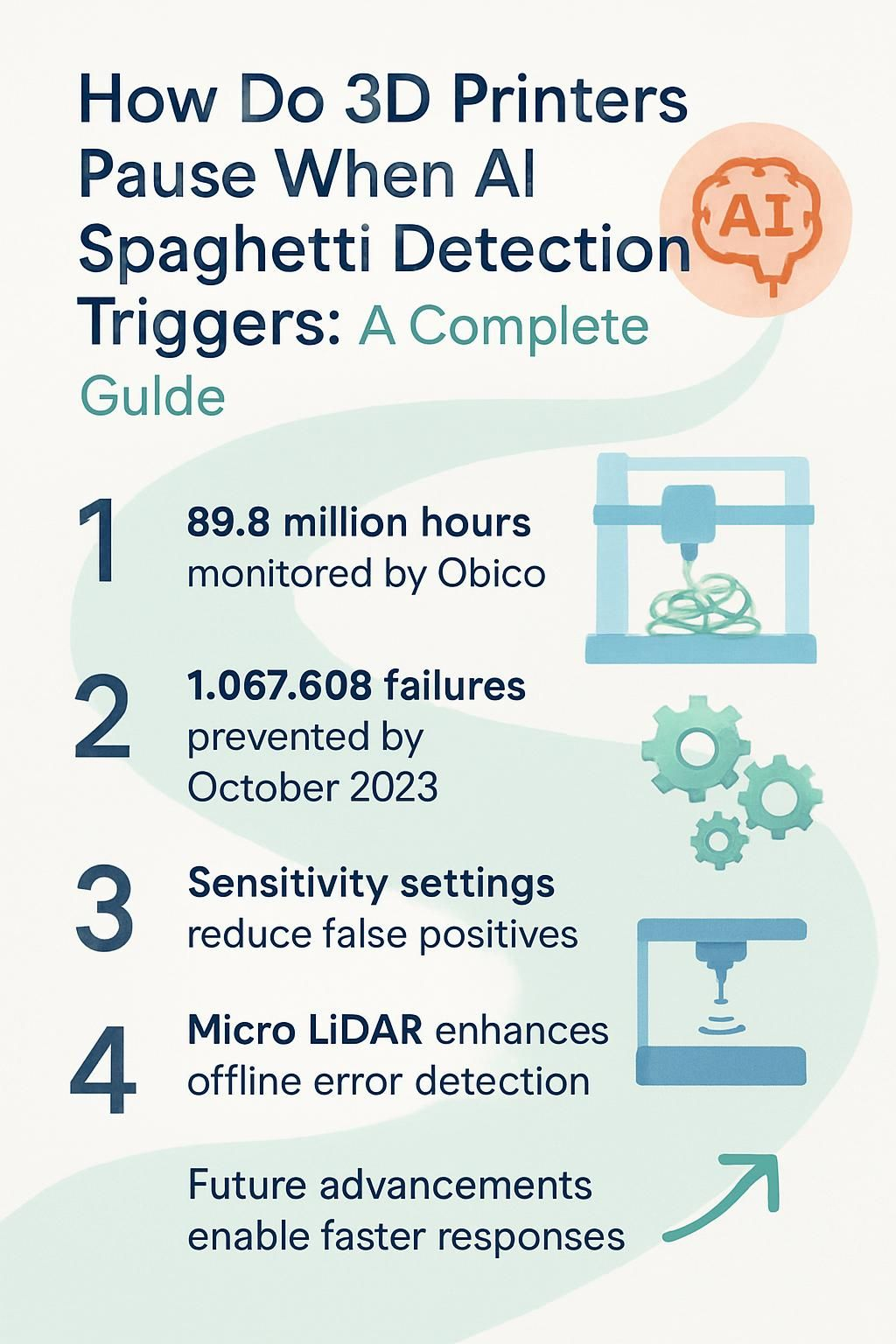

- AI spaghetti detection uses cameras and machine learning to spot print issues, saving time and material. Systems like Obico have monitored over 89.8 million hours of printing and prevented 1,067,608 failures by October 2023.

- Real-time monitoring sends alerts instantly when problems arise. Tools like Obico and Creality K1 Max pause prints automatically to minimize waste and prevent hardware damage.

- Adjustable sensitivity settings help reduce false positives while catching real filament errors during prints. Features from OctoEverywhere or Cloud 3D Print’s AEye Assistant allow better control based on the printer setup.

- Advanced systems like Bambu Lab use Micro LiDAR technology paired with cameras for precise error detection during prints while working offline for data privacy in LAN mode.

- Future advancements include cloud-based integration and smarter machine learning models that ensure faster responses, fewer errors, and improved printer performance over time.

How AI Spaghetti Detection Works in 3D Printing

AI watches your 3D printer like a hawk. It spots problems, such as messy extrusions, using smart cameras and clever algorithms.

Identifying anomalies during the print process

AI detects anomalies by spotting irregular filament patterns. Spaghetti detection relies on machine learning trained on millions of print hours, like Obico AI monitoring over 89.8 million hours and catching 1,067,608 failures.

When the printer extrudes too much or creates tangled messes, cameras pick up these issues fast.

Computer vision works with sensors to monitor every layer in real time. Strange shapes, gripper misalignments, or broken extrusion paths trigger alerts instantly. This reduces waste and prevents hardware damage before things spiral out of control.

Using cameras and machine learning for detection

Cameras play a major role in spotting spaghetti failures. For instance, the Bambu Lab X1-Carbon uses a nozzle-mounted camera to capture clear images during printing. Creality K1 Max relies on its AI-powered camera to detect improper extruding or layer shifts fast.

These cameras send real-time data about issues back to the system.

Machine learning reviews these images for signs of failure like stray filament strands or unusual patterns. Nexus AI works with OctoPrint to analyze print behavior and catch errors early.

This smart analysis helps stop waste before it gets out of hand, saving time and materials effectively.

Key Features of AI Spaghetti Detection Systems

These systems keep a sharp eye on your print, spotting issues before they get out of hand. They work in real-time, stopping problems while saving time and material.

Real-time monitoring and notifications

Real-time monitoring keeps an eye on your 3D printer as it works. Systems like Obico use cameras and AI to spot issues fast. If spaghetti detection kicks in, the system sends alerts right away.

These notifications can pop up on your phone or email, helping you act quickly before things get worse.

“Obico’s system offers live updates you can trust,” says many users who rely on it daily.

Adjustable sensitivity levels

Sensitivity settings let users customize how AI detects spaghetti messes. OctoEverywhere’s Gadget, for example, allows fine-tuning to match different print scenarios. This flexibility helps avoid false alarms while stopping actual issues on time.

Cloud 3D Print’s AEye Assistant also shines with its adjustable tools. Users can tweak detection levels based on filament type or camera placement. Balanced sensitivity reduces missed detections and unnecessary interruptions during prints.

Automatic print pausing mechanisms

Adjustable sensitivity settings play a key role in detecting spaghetti issues, but stopping the printer is where action truly matters. Automatic print pausing mechanisms take over once the system identifies an error beyond set thresholds.

For example, Bambu Lab AI instantly pauses printing after spotting a major issue like excessive filament clumping or misalignment.

Creality K1 Max also halts operations and alerts users as soon as detection kicks in. OctoEverywhere uses its advanced gadget for similar results, ensuring swift response times to minimize waste.

These systems don’t just pause prints; they buy time for you to fix the problem without losing most of your material. It’s not magic, but it feels that way!

Popular AI Spaghetti Detection Systems

Several AI systems now specialize in spotting spaghetti issues during printing. Each offers features suited for different printers and user needs.

Obico AI Detection System

Obico’s AI detection system monitors 3D prints in real-time to catch spaghetti errors fast. Powered by machine learning and cameras, it has tracked over 89.8 million hours of printing.

This powerful tool detected more than 1,067,608 print failures and saved around 23,487 kilograms of filament.

It alerts users instantly while pausing the print automatically if needed. With adjustable spaghetti detection sensitivity levels, it fits different user needs easily. Over 100,000 people already trust this system for reducing waste and preventing damage during tricky print jobs.

Bambu Lab AI-Powered Spaghetti Detection

Bambu Lab uses advanced AI for spaghetti detection. It combines Micro Lidar technology with cameras to analyze every frame of the print process. If it detects enough errors, it pauses the printing automatically.

This avoids wasting filament and prevents damage to your printer.

The system works offline in “LAN Only” mode, keeping data private. Adjustable sensitivity lets users fine-tune how often detection triggers. Its real-time monitoring ensures quick action before things go wrong.

Next, we explore Creality K1 Max AI Features that bring their own twist to 3D printing innovation!

Creality K1 Max AI Features

The Creality K1 Max takes AI spaghetti detection up a notch. It uses advanced LiDAR technology to scan the first layer with an impressive 1 mm resolution. This ensures precise monitoring right from the start of the print.

An AI camera steps in to spot spaghetti failures, foreign objects, and debris during printing. Once issues are detected, it pauses the process automatically and alerts users in real time.

These features reduce material waste while protecting hardware from potential damage. Its user-friendly setup makes troubleshooting easier for beginners too!

OctoPrint with Nexus AI Integration

OctoPrint with Nexus AI Integration offers a powerful open-source solution for detecting print failures like spaghetti messes. It operates on local servers, keeping data secure while using minimal hardware.

A connected camera monitors the printer in real-time, scanning for issues through advanced algorithms.

If an error is spotted, the system pauses the print automatically and sends email alerts to notify you. Users can fine-tune settings, adjusting sensitivity levels based on their needs.

This feature saves both time and material waste by stopping failed prints early without constant supervision.

OctoEverywhere AI Detection

Building on Nexus AI’s integration, OctoEverywhere steps in as a powerful cloud-based solution for detecting spaghetti problems. It uses advanced machine learning to catch print failures early, even from remote locations.

This system works with live camera feeds and analyzes them to spot issues like tangled filament.

The “Gadget” feature adds flexibility by giving remote control without needing the same network. Users can pause prints or share live links of their printer stream easily through mobile apps.

With real-time monitoring, it reduces waste and lowers the risk of hardware damage while keeping users informed anywhere they go!

How 3D Printers Pause When Spaghetti Detection Triggers

When the system spots spaghetti, it sends a quick signal to the printer. The machine then stops printing right away, waiting for your next move.

Detection to signal transmission

AI systems use cameras to watch the 3D printing process. They snap images and analyze frames for issues like spaghetti-like messes. Machine learning models quickly spot these problems by comparing what they see with trained data.

Once an error is found, the system signals the printer’s controller board to pause immediately. This signal moves through wired or wireless connections, depending on your setup. The whole process happens fast, minimizing waste and preventing damage before it gets worse.

Automatic pausing protocols

Printers like Bambu Lab and Creality K1 Max react instantly to detected errors. Once spaghetti detection identifies a problem, the printer sends a signal to pause the operation. This process happens in real-time, stopping wasted filament from piling up.

Cloud-based systems, like Cloud 3D Print’s AEye Assistant, can even pause prints remotely. These features protect your printer while minimizing material waste during long jobs. Next comes how users engage after these pauses for smooth recovery steps.

User intervention after the pause

After the printer pauses, users often get a notification. This alert informs them about potential spaghetti issues. At this point, manual inspection becomes crucial. Check the camera feed or inspect the print directly to confirm if there’s actual filament waste.

Once confirmed, clean up any tangled filament or remove errors from the build plate. Restarting may require adjusting settings like sensitivity on your spaghetti detection system to avoid false alarms later.

Always ensure proper setup before resuming printing to prevent repeat errors and wasted materials.

Challenges and Limitations

False alarms or poor camera setup can mess with results, making detection tricky—find out how to handle this!

False positives in detection

AI spaghetti detection systems can sometimes mess up. They might pause a 3D print even when there’s no real issue. This is called a false positive. Smaller datasets, like in Nexus AI, often increase these mistakes since the system lacks enough examples to learn properly.

A misread shadow or stray filament piece may trigger detection unnecessarily.

Poor camera placement makes things worse too. If the angle isn’t clear, the machine may mistake normal printing for trouble. Adjusting spaghetti detection sensitivity helps reduce such errors, but it can’t eliminate them entirely.

While frustrating, these pauses protect your printer from bigger problems down the line!

Dependence on proper camera placement

False positives get worse with poor camera placement. Cameras need a clear view of the nozzle and print area for accurate spaghetti detection. Systems like Obico or Nozzle Ninja often use nozzle-mounted cameras to keep a close eye on the filament.

A bad angle can block critical details, leading to missed errors or false alerts. Even small shifts in positioning can affect detection sensitivity. Make sure your camera is stable, properly lit, and focused directly on the printing zone for better results.

Why Didn’t My Creality Cloud AI Stop or Pause Print?

Creality Cloud AI might fail to pause a print due to detection errors or sensitivity issues. The AI camera and LiDAR on the Creality K1 Max scan for Spaghetti Failures, debris, or foreign objects.

But poor lighting, bad camera angles, or low spaghetti detection sensitivity can confuse the system. Sometimes the printer doesn’t recognize certain failures clearly enough to act.

Closed systems like Creality’s limit customization compared to open-source options like OctoPrint with Nexus AI. Adjusting settings isn’t always as flexible, which might lead to missed signals during real-time monitoring.

Understanding how these limits affect your prints highlights ways AI impacts success rates. Next up: exploring how AI reduces waste and prevents damage!

Benefits of AI-Powered Spaghetti Detection

Stopping spaghetti messes saves materials and keeps your printer safe. These tools make prints smoother, cutting down on wasted time and headaches.

Reducing material waste

AI spaghetti detection saves filament, plain and simple. Obico reports it has already saved over 23,487 kilograms of material. That’s a lot of plastic kept from landing in the trash or clogging machines.

Faulty prints waste both time and money. By pausing as soon as an error starts, these systems stop extra layers from piling onto failures. Less waste means less time cleaning up disasters too.

It’s like stopping a flood at its source instead of mopping endlessly after.

Preventing potential hardware damage

Automatic pausing systems help avoid damage to your 3D printer. Spaghetti detection stops the print before melted filament clogs the nozzle or jams the extruder. For example, Creality K1 Max uses AI to catch errors early, lowering the risk of motor strain or blockages.

Real-time monitoring also protects crucial parts like the hotend. If issues continue without action, they can lead to overheating or circuit wear. Systems like Bambu Lab identify problems fast, saving both time and repair costs while keeping your printer safe from harm.

Ensuring higher print success rates

AI spaghetti detection helps catch errors early. Systems like Obico, which has detected over 1,067,608 failures by October 2023, prevent small mistakes from becoming big disasters.

By stopping prints when issues arise, material waste and frustration are cut down.

Cameras paired with machine learning spot problems fast. With fewer missed detections and quick responses, printers avoid costly damages. This sets the stage for discussing future integrations in advancing this technology further!

The Future of AI Spaghetti Detection in 3D Printing

AI is set to make spaghetti detection faster and smarter. Expect more precise systems that adapt better during prints.

Advanced machine learning models

Advanced machine learning models process massive data sets to spot patterns. These systems learn from past mistakes, improving detection accuracy over time. In 3D printing, they study images and use algorithms to flag spaghetti-like issues during a print.

New updates come often through Experience Improvement Programs. These programs feed real-world user feedback into the AI model, sharpening its skills further. Such improvements help reduce false positives while boosting real-time monitoring efficiency for smoother operations in 3D printing tasks.

Next: Integration with cloud-based systems…

Integration with cloud-based systems

Cloud-based systems give 3D printers smarter control. They allow centralized monitoring through platforms like Cloud 3D Print. This means users can track prints remotely and stop errors instantly if spaghetti detection triggers.

Private Cloud Deployment adds safety and boosts AI capabilities. These setups process data faster, ensuring smoother automatic pauses during errors or anomalies. Combined with machine learning, cloud integration cuts wasted filament while keeping hardware safe from damage.

Conclusion

AI spaghetti detection is a game-changer for 3D printing. It spots errors fast, pauses prints to save material, and protects your machine. With systems like Obico and Bambu Lab leading the charge, prints are more reliable than ever.

As technology grows smarter, expect even fewer failed designs. The future of 3D printing looks brighter with these tools in action!

For in-depth insights on addressing issues with Creality Cloud AI, check out our detailed guide here.